Create a lean site and enjoy a quality life to the fullest

Release date:2025-06-18

On the front line of rubber production, on-site management is the cornerstone of efficiency and safety. To continuously enhance the factory's management level, we take "5S management" as the core, focus on the dead corners of on-site management, and through improvement actions involving all staff, combined with the monthly "Best Improvement evalsuation" and Uniqlo's purchase reward mechanism, integrate the concept of lean management into every detail of production. This not only optimizes the working environment With Uniqlo's brand spirit of "LifeWear - Clothing for Life", it inspires employees to pursue a quality life and achieves a dual improvement in production efficiency and humanistic care.

1. Confront the blind spots of 5S management on site directly

From "invisible" to "no blind spots", the production environment of rubber factories is complex, with dense equipment and high material mobility. There are often blind spots in cleaning, disorderly stacking of tools, and blurred labels and other 5S management blind spots.

We have established a "reporting mechanism for management blind spots in the workplace" and a "reporting mechanism for management blind spots in non-workplace areas" through full participation in inspections, regional responsibility zoning, and constantly identifying and improving blind spot contents, adhering to continuous improvement. This coincides with Uniqlo's philosophy of "striving for excellence, honesty and transparency, and customer first".

Second, full participation

Activate the creativity for on-site improvement. I am responsible for my area. Each employee is assigned a responsibility area. From sorting and straightening to on-site improvement, from cleaning equipment to optimizing signs, the 5S standardization has been implemented in every operational detail. This also echoes Uniqlo's brand spirit of "people-oriented", emphasizing that employees are the core driving force for management optimization.

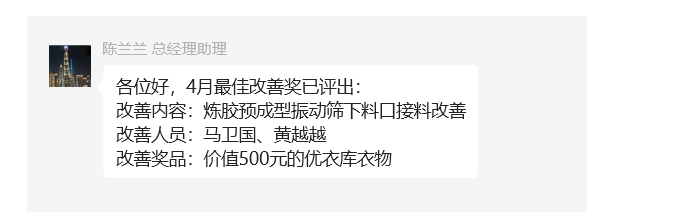

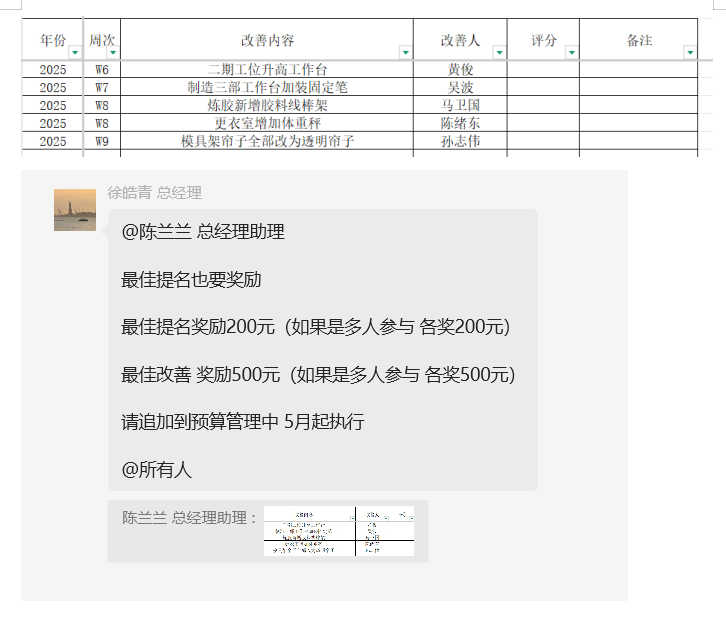

Iii. Monthly Best Improvement and Nomination

To stimulate the enthusiasm of all staff to participate, the factory holds a "Best Improvement evalsuation" activity every month. Both the best improvement and the best improvement nominations will be rewarded with a purchase from Uniqlo. Rewarding Uniqlo for purchasing clothes instead of directly offering cash rewards not only meets the actual needs of employees but also naturally conveys Uniqlo's product philosophy of "high cost performance and high functional design".

Four. Continuous Improvement

The environment in the factory is getting better and better, work is getting smoother and smoother, and more importantly, an atmosphere of full participation is gradually taking shape - employees are shifting from "passive execution" to "active optimization", and gradually transforming the 5S concept into professional habits. Through the collaborative efforts of all employees, standardized rectification and Uniqlo's reward mechanism, the dull management tasks are transformed into creative team actions. Just as Uniqlo advocates "Serving Life" - enhancing the quality of life through high-quality products, the factory also hopes to continuously improve and enable every employee to create value in an efficient, safe and comfortable environment. Enjoy the wonderful balance between work and life.

Last article:Cleanliness inspection

Next article:None